Web Inspection Systems

MRP Automatisierungstechnik

Track Inspection Systems

After several years of development time, MRP introduces the new web inspection system MRP-WIS2008. MRP-WIS2008 has been designed for an efficient and reliable web inspection of high-quality materials such as paper, film, metal and nonwoven and is inter alia used for detecting defects as well as for coating inspections. It is a modular web inspection system that is based on the latest camera, transmission and il-lumination technologies. Thus, it enables all inspection tasks regarding your production and/or subsequent processing chain. Depending on the task at hand, MRP provides a wide range of assemblies and system structures, which are selected and exactly adapted to meet your requirements and to solve your tasks. In terms of web width and web velocity, the MRP web inspection systems MRP-WIS2008, can virtually be adapted both technically and economically, to any production facility.

Reflected Light & Transmitted Light Systems

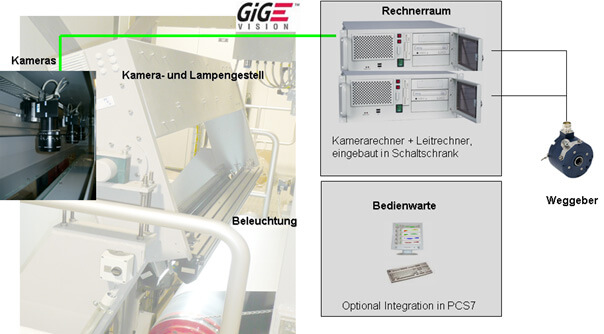

System structure

Depending on the product and the to be inspected areas with defects, different basic systems/assembly variants will be installed. In this context, MRP makes the following distinctions:

- Transmitted light inspection

- Incident light inspection

- Transmitted and incident light inspection

The assembly variants enable illumination arrangements for light and dark field.

Generally line scan cameras with resolutions of 2048 or 4096 pixels are used for image recording. Aperture fluorescent tubes, UV-fluorescent tubes or LED luminaries with different wave lengths (white light, blue light, red light or infrared) are available for illumination purposes. Based on the task definition, we select the best possible attuned system of camera – and lighting.

Gigabit Ethernet connects the line scan cameras to the camera computer, which detects and classifies the defective areas based on the transferred image information. The defective areas are displayed and ar-chived according to customer specification by the master computer. Service functions and parametrisations are also possible.

An automatic control of the light intensity enables consistent inspection performance regardless of the age-ing of the lamps, of dust and dirt or changes of the product opacity, e.g. in the case of change of varieties.

If required, the defective areas can be marked at the face side by a labelling device or a printer can be marked. Alternatively or additionally, a transfer of the defective areas to a subsequent processing machine (e.g. rewinder) is also possible. Thus, so-called target systems can be implemented.

MRP-WIS2008 has a modular design and can be installed as a client/server structure. Thus, multiple oper-ator stations are possible. Furthermore, remote access from any internet workstation is also possible.

* In our laboratory, we gladly perform a free sample examination with logging of your defective areas. This feasibility analysis represents the basis of the functional guarantee for an inspection system to be installed at a later stage.